WHAT ARE THE WEIGHT LIMITS FOR CASTER WHEELS?

How do you need to move objects (furniture or shelves) in your house or offices and you just wish there was a simpler way of doing it without lifting? At one point or another, we must have been in this situation, and we keep wondering and thinking to ourselves, “how do I do this?”

Well, the solution is not far-fetched, if only you know where to look. Health and safety regulatory bodies warn against lifting heavy objects because of the health risk it can cause. Improper handling, Pushing, pulling, and lifting of heavy objects can result if injury or bone deformation to mention but a few.

Since the invention of wheels, casters are amazing in the amount of convenience they offer. They offer extra utility to whatever they are added to especially furniture at home, carts at the supermarket, and even in industrial settings where heavy lifting is done. It’s possible that you may have come across one of these amazing wheels and even used them without noticing or knowing what they are called.

Casters can best be described as a wheel that is housed or fixed in a metal shelter. It is accompanied with either bolt and connected to a steel plate with the aid of screws. They can roll in all directions but are often designed to move in a rigid path. Sometimes, they are made to rotate 360 degrees to serve a specific purpose.

They come in different types, and most common kinds feature a single wheel, dual, and ball wheels. All of these have unique advantages as well as limitations. We will discuss this further in later parts of this article. Your choice of caster wheel is determined by lots of factors, some of which include but not limited to; the environment where it's going to be used, the amount of load it will carry, cost, ease of replacement (if the need arise), and lots more.

What are caster wheels made from?

It may interest you to know that casters are made from different materials, and they also come in unique designs. We have casters made of plastic wheels, nylon, rubber, stainless steel, urethane threads, and even iron. These materials are chosen because of the level of durability they have, and how friendly they are on the surface they will be used upon. Using the wrong kind of caster wheel on your floor may end up causing some damages like leaving marks on them, creating cracks on floor finishes, and even breaking them.

How can you choose the best caster wheels?

Delicate floor surfaces require lightweight and smooth caster wheels in order not to set off rapid deterioration. So, here are crucial factors you should consider while making your choice of the Caster wheel.

Type of flooring

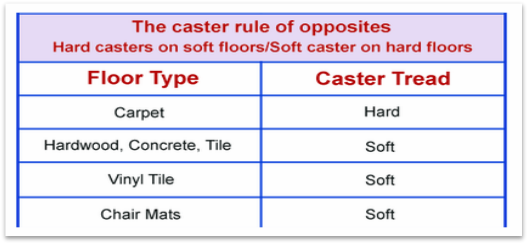

Like we discussed earlier, the nature of your floor surface or finishes determines what kind of caster wheel should be used in that space. It is often advised that plastic wheels should be used on floors with carpet finishing or surface.

Nylon caster wheels are ideal for concrete floors and general industrial settings. If you are to use casters on hardwood and tile floors, it is best you opt for more durable casters like the one made from urethane. Lastly, where does iron casters go? Casters made from iron should be limited to factories and warehouses.

Is the caster wheel fixed or swivel?

Your choice of either a fixed or swivel caster is very much dependent on the application regardless of the size, and material from which the wheels are made. We will attempt to explain this briefly. A rigid plate mounted caster is fixed to the item it is transporting. In this case, the stem of the caster (which is the part of the caster where the wheel is attached) and the plate are molded as a single unit. Even though sometimes, they are attached separately.

The plate is often made in a square shape with holes drilled on each corner. The caster will then be attached to the item using screws. These types of plates don’t move; hence, the name “rigid top plate casters.”

The swivel casters are pretty much the opposite of the rigid caster wheels. In this setup, the stem; also known as the mounting and the plate are molded and constructed to move independently as two separate members or units.

This type of casters allows for 360 degrees rotation due to its design and enhances maneuverability. Most times, the major difference between these two is cost. The swivel caster wheels are more expensive compared to the rigid casters, and the reason is that rigid casters undergo easy manufacturing, unlike the complex methods involved in making swivel top plate casters.

What is the expected weight capacity?

This is the highlight of this article, and that’s why saved it for last. You need to know the weight limitation of your caster. Better knowledge of this, helps you make a more informed decision during selection and purchase.

One easy way to go about this is by simply dividing the load the caster will carry by 4 (for a 4-wheel caster). This helps you calculate the load capacity of each caster. There are other ways of doing this, but this is the easiest approach.

Once you can determine the weight capacity of the caster is, you can go ahead and make your choice. Manufacturers do publish the capacity of their casters to enable you to decide on what you want. There are classifications for load and are broadly classified as light, medium, and heavy loads. The outcome your calculations determines the category of your intended load.

Factors affecting weight capacity of Caster Wheels

The environment or exposure conditions in which the caster will be used also play a significant role in your selection. You should be able to tell if the workspace is humid, is the floor protected (like we mentioned earlier), how is the sunlight intensity. Is the caster prone to chemical attack or corrosion? All of these are items you must have checked on your list.

You must also have it in mind that the result from your calculation may not reflect the actual weight capacity because some other factors were not put into consideration. These factors include the nature of the wheel material and the bearing style, among others. Let’s see if we can illustrate further with a simple calculation. If you have a 4-wheel cart that is expected to carry 1000lbs load. Dividing this value by four will give an estimated weight capacity of 250 lbs. for each caster.

However, the total load of 1000 lbs. must be evenly distributed on the caster wheel. In real life, a moving cart is expected to rock back and forth when in motion. This movement could lead to uneven distribution of the weight on only two or three of the wheels. Due to this high probability, there is a need to adopt a certain factor of safety to accommodate such scenarios where the equipment is unevenly loaded, shifts, or makes an impact with other objects while in motion.

Here are other factors that affect the weight capacity of caster wheels. You will appreciate these more if you are technically oriented. Size, width, and the profile of the wheels also help the casters to support a greater load.

More Tips!

· Wheel diameter

The larger the wheel diameter, the more weight the caster can support. Why? The larger the wheel diameter, the greater resistance it will offer when it hits obstructions like debris or rough pavement. The higher diameter wheel has also been found to roll easily compared to slender wheels.

· Tread widths

Likewise, caster wheels with wide treads can support greater loads when compared to those with narrow treads.

· Tread profile

Flat treads last longer, but round profile tread rolls easily. Also, flat profile treads can withstand more weight and distribute the load evenly over a larger area compared to their rounded counterparts.

· Wheels made from hard materials like cast iron, steel offer greater weight capacity compared to wheels made from soft materials. They can support loads of up to 6000 lbs. compared to an expected 2000 lbs. capacity from soft wheels.

Hopefully, this article has given you more insight on casters. You will find this information important when making a choice of caster wheels and determining their weight limits. We will explore more ideas on this subject in a later post. Stay tuned!