Piano Casters: Why they are Useful

Introduction

Since the dawn of mankind, the use of the wheel has provided us with the ability to build and move in a way that is nothing short of miraculous. Most historians and anthropologists attribute mankind’s advancements as a species to the wheel and fire. Attaching a wheel to any inanimate object instantaneously makes it mobile. This concept of making heavy and immovable objects move with ease lead to the discovery of wheel casters. While some form of casters have been used since early human civilization to move objects, it was only in 1879 that David A. Fisher patented what is now known as the modern caster.

In this article, the focus is on piano casters, their origins, classifications, materials and components as well as their advantages and disadvantages.

The Piano

Probably the most recognizable musical instrument in the world, the piano was invented in Italy in the early 1700s. It is classified as an acoustic stringed instrument. The piano is played when the musician strikes the keys that in turn move hammers inside the piano body and cause them to strike the strings. The piano gained immense popularity since its inception thanks to its key role in a variety of musical forms. It is most notably present in western classical, jazz, rock, pop and blues music genres. It plays a central role in all these genres and is also the medium of choice for composers and lyricists as it offers the ability to produce complex melodies and polyphony by a single musician.

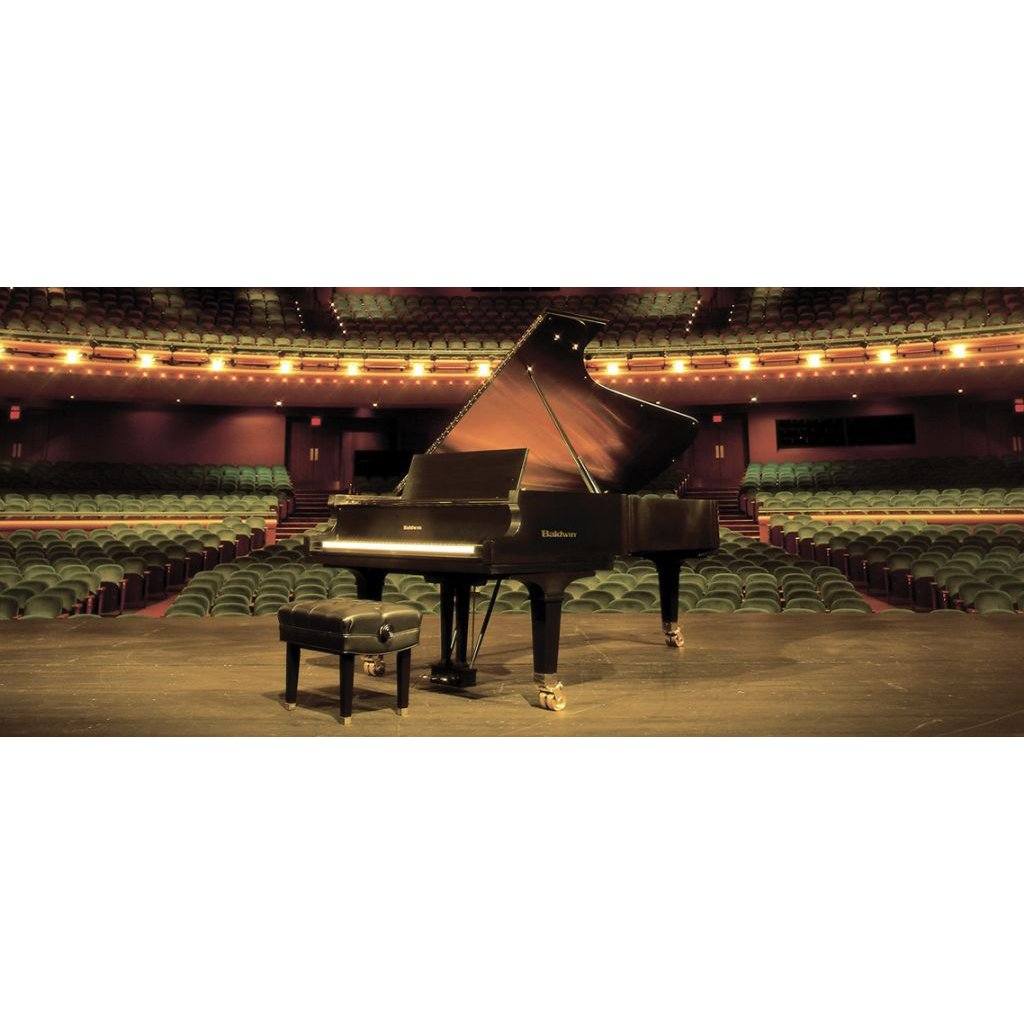

A Grand Piano Source: Yamaha

A Grand Piano Source: Yamaha

The piano can be broadly categorized into three subgroups: the grand piano, the upright or vertical piano and the digital piano. The grand piano is the most classical interpretation of the instrument. The name is well given as these table-like long and heavy pianos are a staple in concert halls, thanks to their clear, brilliant and ringing sounds.

An upright piano relies on a vertical orientation of strings in its body. They are usually much smaller than grand pianos and produce a slightly lower quality of (although still stunning) acoustics.They are commonly used in churches, music studios and homes.

A Yamaha U1 Upright Piano. Source: Amazon. Inc.

A Yamaha U1 Upright Piano. Source: Amazon. Inc.

The Casters

In a generalized sense, a caster is a wheel based support device that is applied under a large, heavy or cumbersome object. The caster enables easier movement of the object by transitioning its movement from sliding motion into rolling motion.

Casters come in various sizes, they are composed of a variety of materials (i.e. plastic, brass, rubber etc.) and they are applied to a diverse portfolio of objects ranging from office chairs, hospital beds & equipment to the gigantic shipyard cranes, which rely on casters to support their movement as they lower container off ships.

The two main types of casters are swivel casters and rigid casters. Swivel casters are capable of additional 360 degree rotation on an axis perpendicular to the wheel axis. This allows them to have a freedom of motion in all directions as well as instantaneous direction change. These are found in office chairs and department store shopping carts. On the other hand, rigid casters do not offer freedom of movement. They are best used in cases when only one or two degrees of motion should be permitted.

Why use piano casters

Pianos; especially grand and upright ones, can prove to be very expensive. The best pianos are handcrafted by a select few brands. Steinway & Sons, Grotrian Steinweg and Yamaha are some of the most successful and high quality piano manufacturers in the world. Steinway & Sons have become synonymous with the modern grand piano. They hand craft orders over a year and sell them for six-figure sums (USD) in some cases (such as their all-black Model D - Concert version).

Pianos are extremely valuable, often passed down from generations. They are also very large and cumbersome and present a challenge to move. They are very delicate and should be handled around with extreme care. They could potentially damage carpeting, hardwood floors and tatami, when placed indoors. The floor damage is often permanent and severe if the piano is of a heavy make. The biggest consideration is the lack of movement. Pianos used to entertain audiences in churches and concerts need to be moved from one place to another on a regular basis. Due to their large size and lack of mobility this is a near impossible task without mechanical assistance. In performance scenarios (i.e use in churches or concerts), the piano is required to move in and out of the stage multiple times a day.

A grand piano can weigh between 500 to 1200 lbs. This is almost half a tonne of force on flooring. Due to the piano’s shape (thin legs holding up the body), this causes a massive amount of pressure to be exerted on the point of contact. Even if the floor is well secured in its foundations, this amount of pressure over time can result in deformation and buckling. Not only does this create a difficulty for the piano player, but also diminishes the aesthetic of the space. This is especially important as pianos are often placed within churches and concert halls where the visual dynamics are a crucial element. The problems emerging from the size, weight, delicate nature and lack of movement of a piano can be quite severe and permanent. To resolve these problems, one can add a simple mechanism to the piano to ease its movement and weight distribution. Piano casters provide a relatively inexpensive and straightforward solution to said problem.

Grand Piano Casters. Source: pinterest

Piano Casters

Piano casters present a simple mechanical solution to the problem arising from the piano’s weight and rigidity. As the piano’s lack of mobility and heavy body are potentially damaging to the flooring space, the mobility and weight generated by casters present a convenient and inexpensive solution to the issue at hand.

Specifications and acceptable uses of various caster types. Source: McMaster-Carr

Specifications and acceptable uses of various caster types. Source: McMaster-Carr

A caster wheel is generally made up of three components: the rig, connector and the wheel itself. The rig is the top part of the caster that allows it to be mounter or applied to an object. Usually, casters would present a bracket-like flat surface upon which the object is mounted. The rig also includes the swivel mechanism in the case of swivel casters. The connector comprises of a yoke that holds the wheel in place, a spring damper to reduce shock vibrations and wheel bearings to reduce friction. Lastly, the caster’s most crucial element is its wheelbase. This consists of one or more wheels, depending on the use. The most common application is one with two wheels.

In the case of large and heavy pianos, casters are attached to the base or legs of the piano (see image), thereby creating an ease of motion when it comes to handling pianos. The wheel of the casters along with piano caster cups reduce the load bearing on the floor, thereby distributing the weight of the piano across a larger surface and preventing damage to the floor space, even upon their movement.

Casters are usually categorized into two main types: rigid and swivel casters. The rigid casters only allow one degree of movement due to the lack of a swivel head. They are structurally stronger than swivel casters due to less joints and moving parts. They are also more stable as the movement of the object placed upon rigid casters is much more stable than that of swivel casters. Rigid casters are most suitable for handling larger pianos such as the concert grand piano due to their advanced motion control and ability to handle a large weight force.

On the other hand, swivel casters present a 360 degree swivel function on the axis perpendicular to the caster wheel axis. This allows for almost unlimited motion and instantaneous direction change. Due to the addition of the swivel component on the caster rig, the movement of the casters is very flexible and user friends. However, this instant mobility and high degree of variation in movement comes at a cost. Due to the presence of additional moving components and free form joints, swivel casters are structurally weaker than rigid casters. They are unable to sustain the same amount of maximum load and are also more susceptible to long-term wear and tear. Due to this, they are best suited to offer mobility or lightweight pianos such as digital pianos and small upright pianos.

A Swivel Caster. Source: pianofortesupply

A Swivel Caster. Source: pianofortesupply

The other differentiating factor for casters is their composition i.e. the material that is chiefly used in their construction. Usually, they are made of plastic, brass, rubber, metal or Polyurethane composite. In the case of plastic casters, they are usually the most inexpensive option. On the downside, they also bear the lowest load threshold between 160 to 200 lbs. Due to their light and smooth structure, they are easy to roll and are readily available. Brass casters are by far the best looking and are often used in Steinway & Sons grand pianos.

They are prone to scratching the floor as brass has a high friction coefficient. Regardless, due to their metal-alloy nature, brass casters provide good support between 400 to 500 lbs of max load. Rubber casters are the most diverse ones available as there are numerous qualities that can be changed. The softer and more flexible ones are capable of bearing 160 lbs while to structurally sound ones are able to bear as much as 640 lbs. Rubber casters are often plainly colored in gray or black and are therefore not as beautiful as brass ones. However, due to rubber’s soft and smooth composition, they do not cause damage to the floor in any case. All-Metal casters are also available. These are very strong and create a large degree of movement. However, as is the case with brass casters, metal casters also cause damage to softer floors such as polished hardwood and carpeted floors. Lastly, we have the Polyurethane composite or PU caster. These are the strongest caster types available with load bearing capabilities between 1000 to 2000 lbs (almost 1 tonne). They are not as susceptible to wear and tear as rubber and plastic casters and carry almost 4 times as much load. Due to PU composite unique properties, they will not cause damage to the floor and offer silent operation, something that is required in places such as churches and concert halls.

A Yamaha Grand Piano with brass casters Source: Yamaha

Piano casters are extremely affordable, with prices ranging from $19.99 to $59.99 for a set of four casters.

Advantages of Piano Casters

Piano casters are excellent tools to facilitate the movement of the piano. They change the inertial nature of the piano into rolling motion, thereby saving time and energy when attempting to move the piano. This is especially helpful in cases where frequent movement of the instrument is required i.e. in churches and in concert halls. Naturally, due to the weight and structure of a piano, an accident pertaining to the instrument can result in previous injury. Due to the ease of movement provided through casters, this is well prevented and hence, the personnel involved in moving the instruments are safe from injury. Piano casters reduce the discoloration and damage to floors. This is subjective as some varieties like rubber and PU composite cause negligible damage while brass and metal ones have potential to cause some damage. Nevertheless, piano casters, when accompanied by caster cups are able to completely neutralize any damage to the flooring. Due to the rolling nature of casters, movement of the piano is relatively quiet. PU composite casters provide the best results in this regard (and in almost every other performance category) due to the unique properties of Polyurethane.

Piano Caster Cups

While casters provide the freedom of moving pianos at will, they may cause damage to the floor, especially in the case of brass and metal casters. The other types i.e. plastic and rubber do not cause damage but are not as eye catching as the metallic variants. Casters are also wheel based which means that they are prone to roll freely when on an uneven or slanting surface. Caster cups help solve these issues when used alongside piano casters.

Piano caster cups are rounded platforms with a central depression that hold the wheelbase of a piano caster. Piano casters are available in plastic, wood or metallic. They are relatively light and small in size (slightly wider than the length of the caster). The most popular piano caster cups are the wooden cups.

Piano caster cups help in distributing the weight of the piano across their wide, flat base. Pianos are heavy and casters alone cannot help redistribute the weight, especially when stationary. Piano casters come in handy when a piano is stored after use or relocation. The casters also provide protection to the floor and prevent any discoloration originating from the piano leg or caster. Naturally, as caster cups lock the wheel’s movement, they help keep the piano safely in place. Lastly, the wooden and brass variants of casters augment the piano’s beauty and help hide the piano caster material.

Piano caster cups are usually available in 3 standardized sizes. These are the 3-½”, 5” and 5-½” variants. These are categorized on the basis of their outer diameter and are between 3-⅜” to 3-⅛” wide in terms of their inner diameters. These cups are highly varied and can be available in any combination of the inner and outer diameters listed.

Things to Consider

Piano casters are categorized by materials and function (swivel vs rigid). One must carefully choose the caster after considering the piano weight and the amount of movement that would occur with the piano.

The size and material of the caster is also important because each piano has an optimal size caster that offers the easiest movement. Considering factors such as piano weight, length, number of legs and width of legs, one must decide on the best caster to accompany the piano.

The installation and placement of the caster must be completed with extreme care so as to avoid uneven movement and lopsided placement. Ensure that the casters are level with one another and located at the very center of the piano leg.

Lastly, ensure that casters with brakes are used for increased stability and control. Remember that caster cups double up as stoppers and provide protection and stability when the piano is stored after use or display.

Resources

1. The Piano: A History. Erlich, C. 1990. Oxford University Press. Oxford, UK. ISBN 0-19-816171-9

2. The Oxford Companion to Music ed. 10. Scholes, P. A., Ward, J. O. 1970. Oxford University Press. Oxford, UK.

3. SteinWay Grands. 2019. Steinway & Sons Brochure. https://www.steinway.com/pianos/steinway/grand

4. About Casters and Wheels. Pp 1424. 2019. The McMaster-Carr Guide. McMaster-Carr. https://www.mcmaster.com/about-casters